As a brand new processing method, laser technology is gaining its popularity in the textile and apparel industry because of its irreplaceable advantages like accurate and fast processing, simple operation, and high degree of automation.

1. Laser Cutting Machine

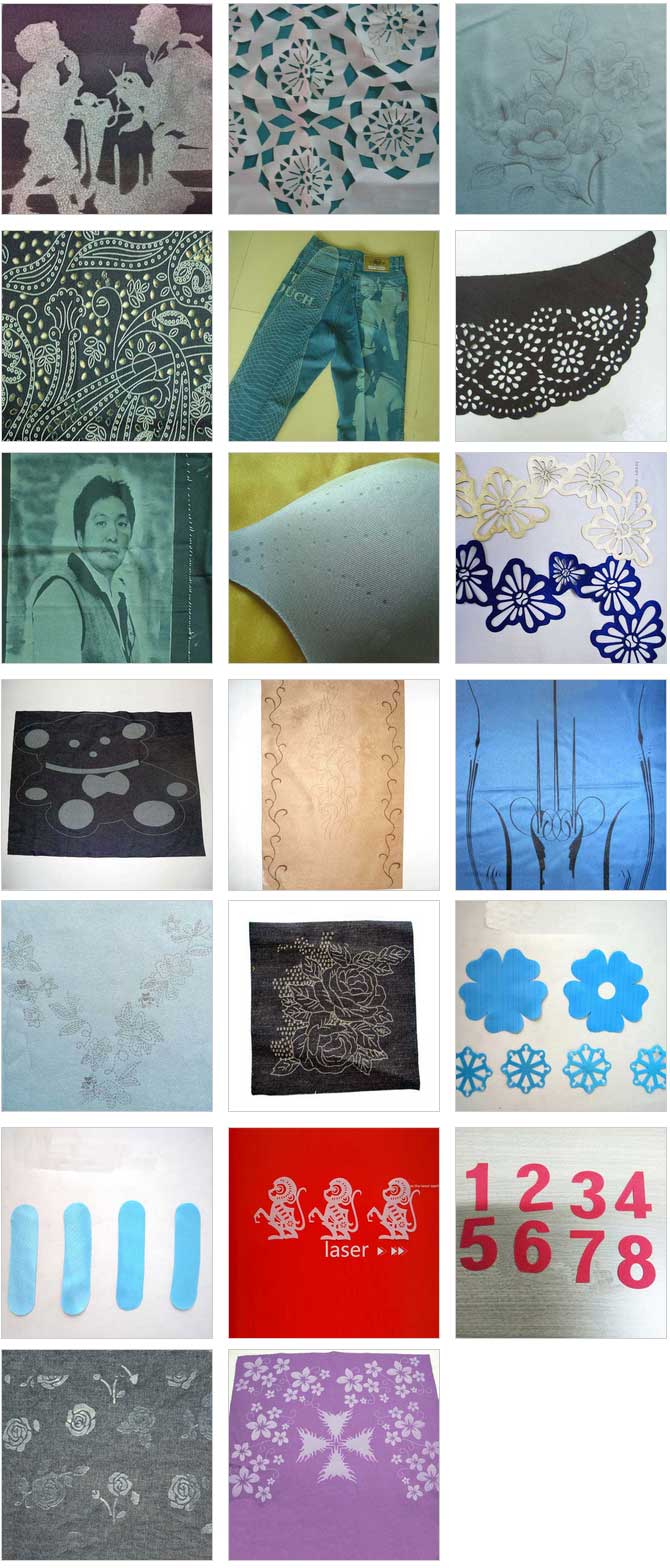

Advantages: while keeping high-precision cutting, laser cutting machine will not lead fabric to any warp or wrinkle. And cutting shape can be easily changed with artwork, bringing more room for creativity. Besides, laser cutting machine is an upgraded replacement for die board processing and thermal cutting. As we know, traditional die board processing or thermal cutting often results in annoying easy-to-off blade, and yellow and stiff kerfs. In contrast, laser cutting machine replaces metal knife with laser and makes it possible to momentarily melt and solidify kerfs, ensuring small and high-quality kerfs with extreme precision.

Laser cutting machine is suitable for proofing high-fashion clothes and cutting special fabrics, leather, knitting embroidery, patch, woven label.

2. Laser Engraving Machine

Advantages: laser engraving is an automatic processing realized by coupling laser engraving machine and laser engraving software, and inputting graphic artwork. Currently, laser engraving is the most mature and widely used laser processing technology. With the capacity of engraving any complex graphics, blind slot and hollow-out pattern, laser engraver is able to make various amazing patterns with many effects like different shades, textures, layers and transitional colors, etc. It also features high degree of automation, simple and convenient operation, high engraving precision and fast engraving speed, catering to the new international trend for apparel processing.

Laser engraving machine is applicable for engraving various patterns on leather shoe, leather boot, leather jacket, garment, denim fabric, etc.

3. Laser Marking Machine

Advantages: laser marking machine boasts high marking precision, fast marking speed and clear marking result, capable of marking all kinds of texts, symbols, patterns on flat and cambered surfaces of hard, soft and fragile products and even air planes. Laser marking machine integrates all the advantages of laser cutting machine and engraving machine, making it possible to precisely mark small and complex patterns on the sheets of metal and organic polymer. Because the mark made by laser marking machine will never wear, it is well suitable for marking various complex and delicate logos on cloth, leather, metal, etc, leading itself to be the best choice for branded apparel processing.

Laser marking machine is ideal for marking logos on all apparel, and some metal buckles, zippers, belt buckles, buttons, etc.

Picture