To make high-power and top-quality laser beams, we always stick to operating at fundamental mode during making laser beam, in case of maladjustment of optical cavity resonator and shape distortion of laser tube due to long-time service, so as to ensure satisfactory high-quality laser beam.

Model: Zn-1250 model 80watts laser tube

High power rate, fast - speed cutting and small size

Origin: Asia and Pacific Area China

Quality standard: International

H.S.Classification: Machinery & Electronics Electr.Element 8541 Semiconductor devices; light - emitting diodes etc.

|

Model |

Rated Power |

Max Power |

length |

Φ |

Catalyze |

Life span |

Warranty |

|

Zn-1250 |

80W |

100W |

1250mm |

80mm |

Yes |

10,000h |

10 months |

|

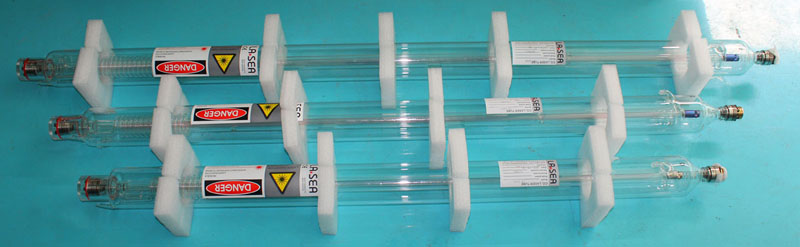

Packing |

GW |

NW |

Size (L x W x H)cm |

Vol weight |

|

Inside carton box Outside wooden box |

18kg |

3kg |

155x35x35 |

38kg |

We will send a new one freely if the tube is broken during transit.

Once received the laser tube, please check again at the first time. We need the damaged record from the courier as the proof before we send the new one free.

Feature

Output Power: Its output power can reach 100w. The production process of the tube is standardized, so the output power and output model are guaranteed. (For other laser tube manufacturers: can’t provide this product)

Long life span: We have catalyst plating in the inner wall of the laser tube. Designing lifespan is 10,000 hours and the warranty is 10 months. (No catalyst technique is used by other model laser tubes. Their lifespan is from 3000 hours to 6000hours and the warranty is only 3months to 6 months)

High performance cost ratio: High output power, high efficiency, and high performance cost ratio.

High photoelectric conversion rate: The output power will decrease for less than 2w when the cooling water’s temperature is 42℃. Its heat productivity is lower than 60w tubes of other brands. (Other brands: The output power decrease rapidly when the cooling water’s temperature is 42℃)

Advantage

Appearance: The tube is sealed by metal material. It is industrial product. (No metal material is used by other manufacturers. Their tubes are handmade and need extra water cooling for front and rare mirrors).

Tube frame: This is exclusive design for Zn series laser tube. You can use it to install our laser tubes into the machine to spare the freight cost. This frame is shockproof and makes sure the tube will not move during the transport.

Length: The length is only 1.25m. It reduces the volume of the machine and minimizes freight cost.

Used for

Zn1250 model CO2 laser tube is featured as high power rate, good model, and fast - speed cutting and small size, which is used for the cutting of fabric, wood, acrylic board cutting, etc.

Benefit

High photoelectric conversion rate: Water Chiller should be equipped. The output power will decrease for less than 1w when the cooling water’s temperature is 42℃. Its heat productivity is lower than 60w tubes of other brands. (Other brands: The output power decreases rapidly when the cooling water’s temperature is 42℃)

Warranty: 10 months, international warranty service,

High performance cost ratio: When you buy Zn1250 model Laser tube, you can spare money for sheet metal, transport. Besides, you get 10 months warranty and the top level after sale service.

![]()

![]()

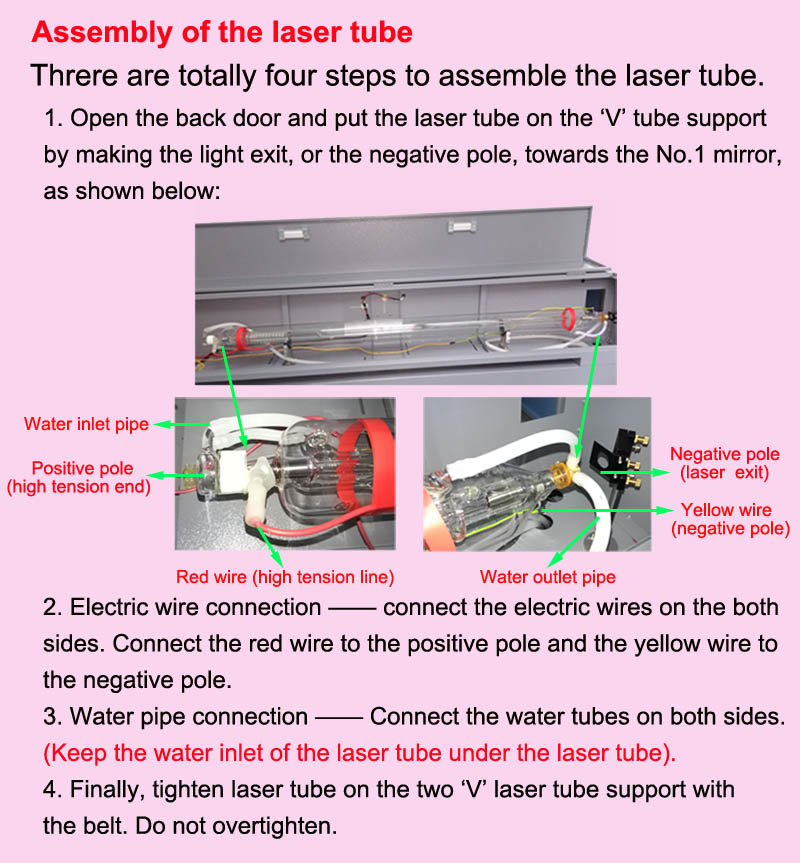

Operating Instruction

Installation Requirement

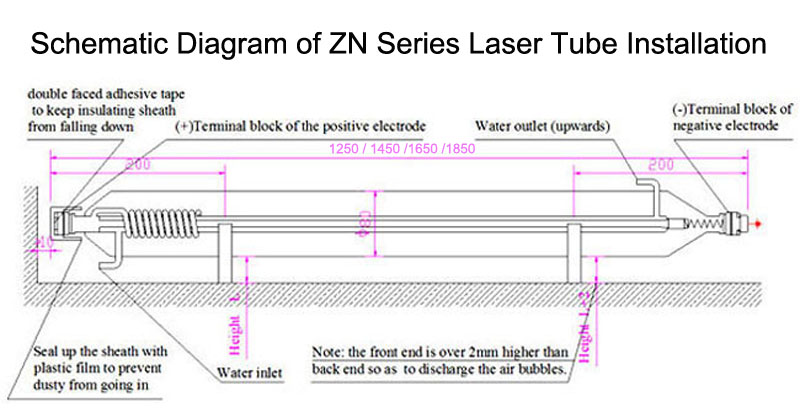

Make sure to follow the operation instructions of model Zn-1250 as shown in the illustration. The dedicated 80watts laser power supply should be equipped. The positive pole is in high voltage (The ignition voltage is 28kv). It may cause the following consequence when it is failed to follow the instruction: Arcing; the inner tube will be punctured by electricity and may cause water leakage.

Operation conditions

• Water cooling: Using purified water; 3 to 5 liter / minute; water temperature: 10℃ - 40℃.

• The operating environment: temperature 2 - 40℃, humidity 10-60%.

• The working current: test current is 22mA. Maximum working current is 26mA. The running current must be kept below 26mA. The life span can reach 10,000 hours if the current is kept below 26mA. The ammeter indicating current must be connected to the negative electrode of the laser tube.

• When it is working under over - high current for long term, the negative pole will appear light yellow, and the life span will be reduced rapidly.

• To protect dust from going into the insulation sheath, please wrap it with plastic film.

Working Performance

• Cutting function.

Key Notes

Do not clean the exterior surface of the output widow mirror with tools such as tampon; otherwise the output power will be seriously affected. The followings are the designated methods to clean up pollution in the exterior surface of window mirror:

1) When the mirror is polluted, do not turn on the laser.

2) Blow the mirror surface sideway with air blower.

3) Spray the pure alcohol on the mirror surface with sprayer.

4) Turn on the laser after the alcohol gets fully volatilized.

5) If the methods above don't work effectively, it is necessary to ask for the professional to use tampon with alcohol to clean the mirror surface from middle to edge. The best solution is to prevent the window from being polluted.

Attention:

It is forbidden to clean the mirror with acetone.

The screw in the front and back ends of the laser tube is not allowed to be moved, otherwise the out power will be declined and even the tube may be scrapped.

Put the acrylic 300mm far away from output mirror, when testing the laser spot.

Safety

The laser beam is invisible light. Please wear protective glasses when debugging the laser. The positive pole is in high voltage. Pay attention to the security marks.

Storage and Transportation Requirement

Pour out cooling fluid in the event of storage and transportation, and cover the output terminal with a dust - proof plastic bag. The storage environment is 2 - 40℃, and the requested humidity is 10 - 60%. Pack the laser as in the original way.

Important notes: it is requested to cement the sponge together with laser tube to prevent the tube vertically sliding during transportation. The sponge in the side of output mirror must be 70mm beyond it, and the sponge in the side of reflecting mirror must be 50mm wider.

Tubes operated in wrong way will not be guaranteed.

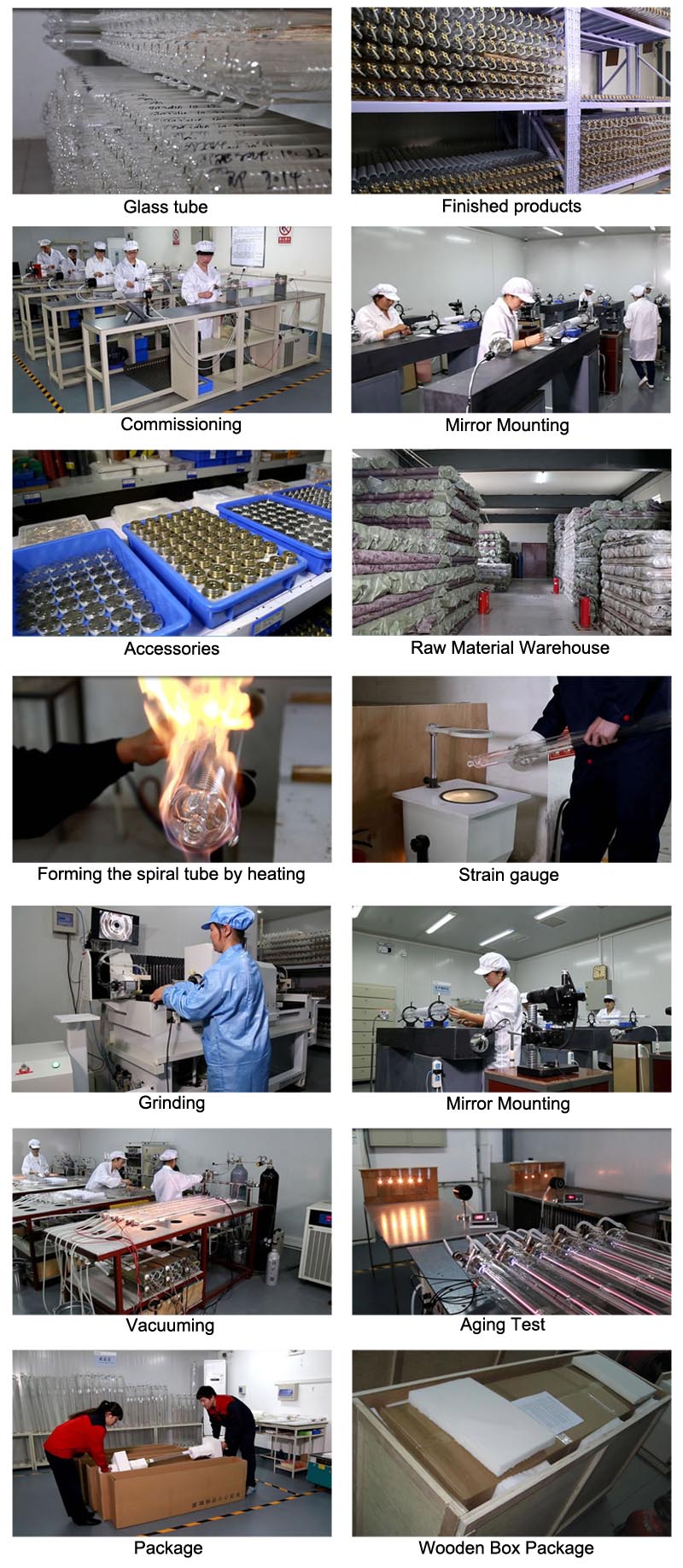

Laser tube manufacturing:

How to check the laser?

The laser power will reduce gradually while using. When the maximum power can’t carve deep enough, please change the laser tube.

We need to exclude other reason of the problem.

Firstly, make sure following things: Cooling - water flows well and bot hot or dirty. When water temperature is higher, laser’s power will drop fast, or even explode the laser. At this time, change it or add more cooling water.

Secondly, make sure the mirrors, lens and light rought are all good.

Thirdly, make sure the electrical power and fanners is working well. When the temperature of electrical power is higher, it will afect the laser.

In fact, laser’s power will reduce slowly. When the laser is all right, light beam in the tube is pink - purple, when it’s near to be finished, the light change to with.

Many Laser Tube on Market, Why Buy From US?

1. Quality

Our factories have passed ISO9001 / 2000 quality certification. Most of our products have CE Certification, FDA Certification and RoHS Certification.

2. Price

Striving to improve efficiency and reduce costs, we have absolute predominance in price by selling products online directly to the end users.

3. Service

For international customer we provide professional technology support on all our products by E-mail within 24 hours or what’s app / Skype online. Any problems about product, we will provide the step by step instruction for you.

4. Spare Parts Supports

We provide all replacement parts for all machines we sold, if you have a parts that break beyond warranty period, you could order it directly from us at reasonable prices. We would post the new parts with step by step instructions on how to replace the parts to you.

5. Satisfaction Guarantee

For the items other than consumable products sold by us, we provide 12 months warranty after shipment. All the extra parts for equipment can be purchased from us.

We offer 14 days 100% satisfaction guarantee on all our machines. If you are not satisfied after receiving an item, within 14 days after actual delivery of such an item, you are allowed to return the item to us and get complete refund, provided the returned item does not affect its subsequent re-selling.

6. Shipping

With professional packing skills to avoid the breakage, we have posted laser tube to worldwide safe and sound, including USA, Europe, Eastern Europe, South America, and Middle East, etc.

PS: To ensure customer get the laser tube fast and safety, we choose TNT/DHL/UPS/Fedex express door to door service flight directly from Guangdong of China. The delivery time is about 4-5 days to most coutry of west Europe and USA. (Please inform us if you want to send the laser tube through other express)

•Your order will be post within 72 hours including weekend after the full payment is cleared.

•The airway bill number for for on-line tracking will be sent after your order is send, please check your E-mail.

Benefits of our lasers?

Lasers Designed Specifically for Engraving & Cutting-Lasers are made in China with high quality and specifically tuned to provide fine cutting and engraving quality.

Power Range Availability (30-180 watts)-Get the exact amount of power you need for virtually any application.

How much power do I need?

25-35 Watts - It is special for stamp carving and simple engraving and thin material cutting, not recommended for thick cutting or dual head applications.

40-50 Watts - Medium production power level for deeper, high speed engraving and slightly thick cutting operations.

60-80 Watts - High production power level provides increased throughput, deep engraving and cutting. Ideal for precision engraving and cutting.

100-180 Watts - Very high production power level that is ideal for heavy cutting and deep, higher throughput engraving. For example, if you want to cut acrylic of thickness of over 3mm (include 3mm); you can choose high power lasers.

Instruction

Using conditions of laser tube

1. Ambient temperature: 10-40

2. Relative humidity: 45%-85%

Cooling conditions

1. Cooling water temperature: 15-30 in summer, in other seasons 20 is better.

2. Cooling water flow rate: Above 6L / min;

3. Water quality: Drinking water and impurities is less than 0.2mm in diameter;

4. Cooling water PH value: 6-9.